Bartek Ingredients

Industry: Industrial Chemical Manufacturing

Project Scope: Global-Scale Production Facility

Powering the World’s Largest Malic and Fumaric Acid Plant with a Custom Production Management Platform

Bartek Ingredients Inc. is a global leader in the production and distribution of malic and food-grade fumaric acid. As part of a large expansion project, Bartek constructed a brand new, state-of-the-art, vertically integrated facility—set to become the world’s largest of its kind.

To manage order fulfillment, coordinate production processes, and provide plant-wide visibility, Bartek required a custom Production Scheduling and Management System (PSMS) purpose-built for their new operation.

PHD Solutions Inc. was selected to design and develop the PSMS from the ground up, leveraging our deep expertise in complex production systems and industrial integration.

Solution

The PSMS was completely custom-designed and developed to be a fully integrated software platform that serves as the digital backbone of the new facility. Key capabilities include:

Technologies Used

Challenges

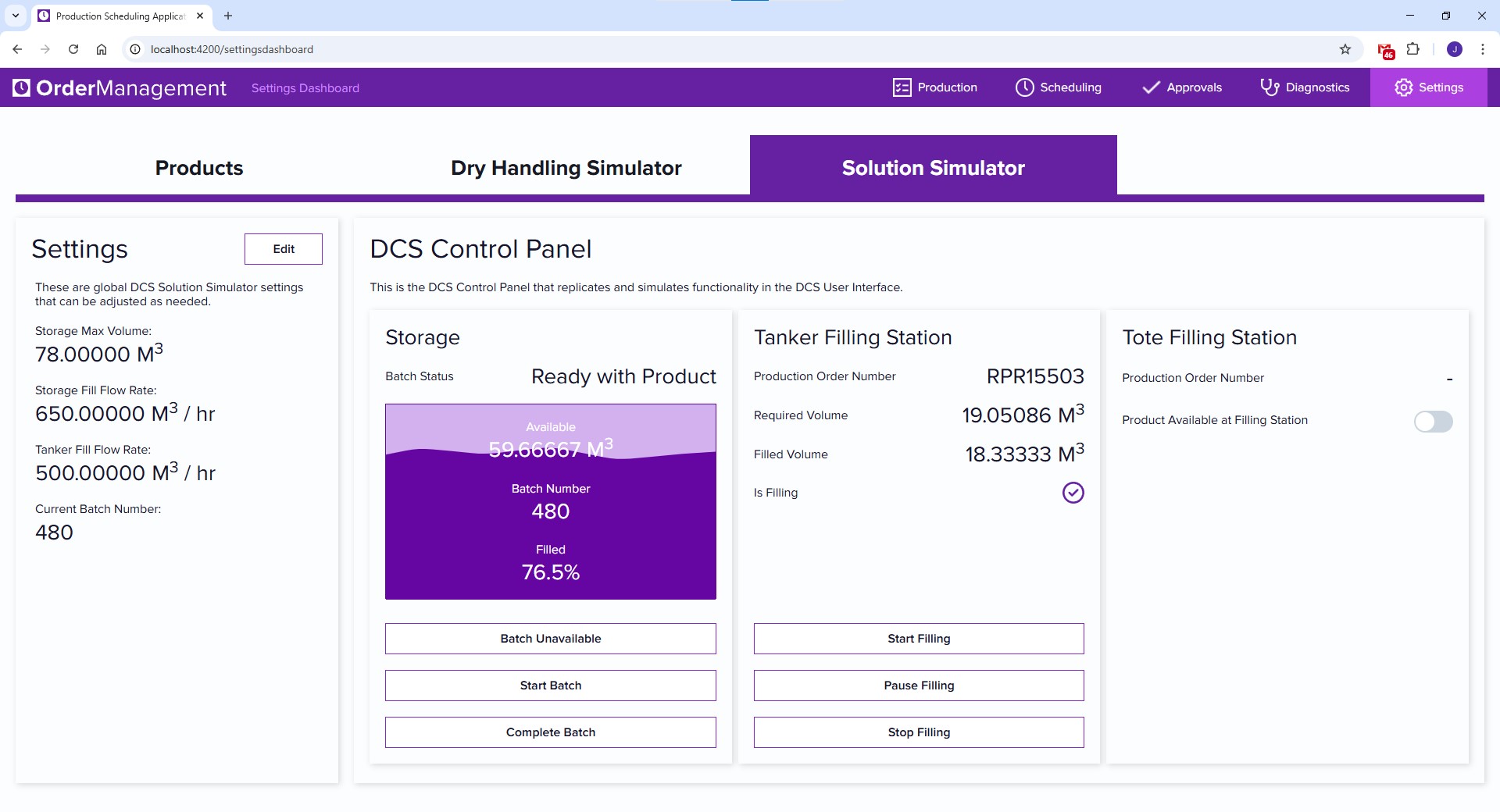

One of the primary challenges was developing a fully featured production platform before the physical plant had been constructed. Building against hardware that did not yet exist required a highly collaborative design process and early investment in the development of a comprehensive digital twin.

This allowed our teams to simulate, test, and validate processes in a virtual environment—minimizing risk and accelerating future commissioning.

As the project matured, additional feature requirements emerged. Thanks to a strong, transparent partnership between Bartek and PHD Solutions, the original vision remained on track while enhancements were implemented without disrupting the core architecture.

Results

As of summer 2025, the PSMS is entering final validation, coinciding with the commissioning of the remaining hardware systems. Feedback from Bartek stakeholders—including plant operators, engineers, and executive leadership—has been overwhelmingly positive.

PHD Solutions is proud to have delivered a robust, future-ready solution that met every milestone across 12 months of active development. We’re excited to continue supporting Bartek’s operations as they move into full-scale production.